Related use case

Ekopak: The Covid-19 pandemic has proven once again that remote working is part of the future.

An Industry 4.0 success story about enhanced productivity, improved delivery reliability and the paperless production plant.

Questions about this case? Contact us!On a mission to create a smart factory, industrial enterprises around the world are investing in new, state-of-the-art digital technology. But what does it take to create the factory of the future? And can they get there in a fast and scalable way?

In this business case, we will take a closer look at Belgian industrial manufacturer Helioscreen, where Factry’s open source-based manufacturing execution system (MES) was recently implemented on the shop floor.

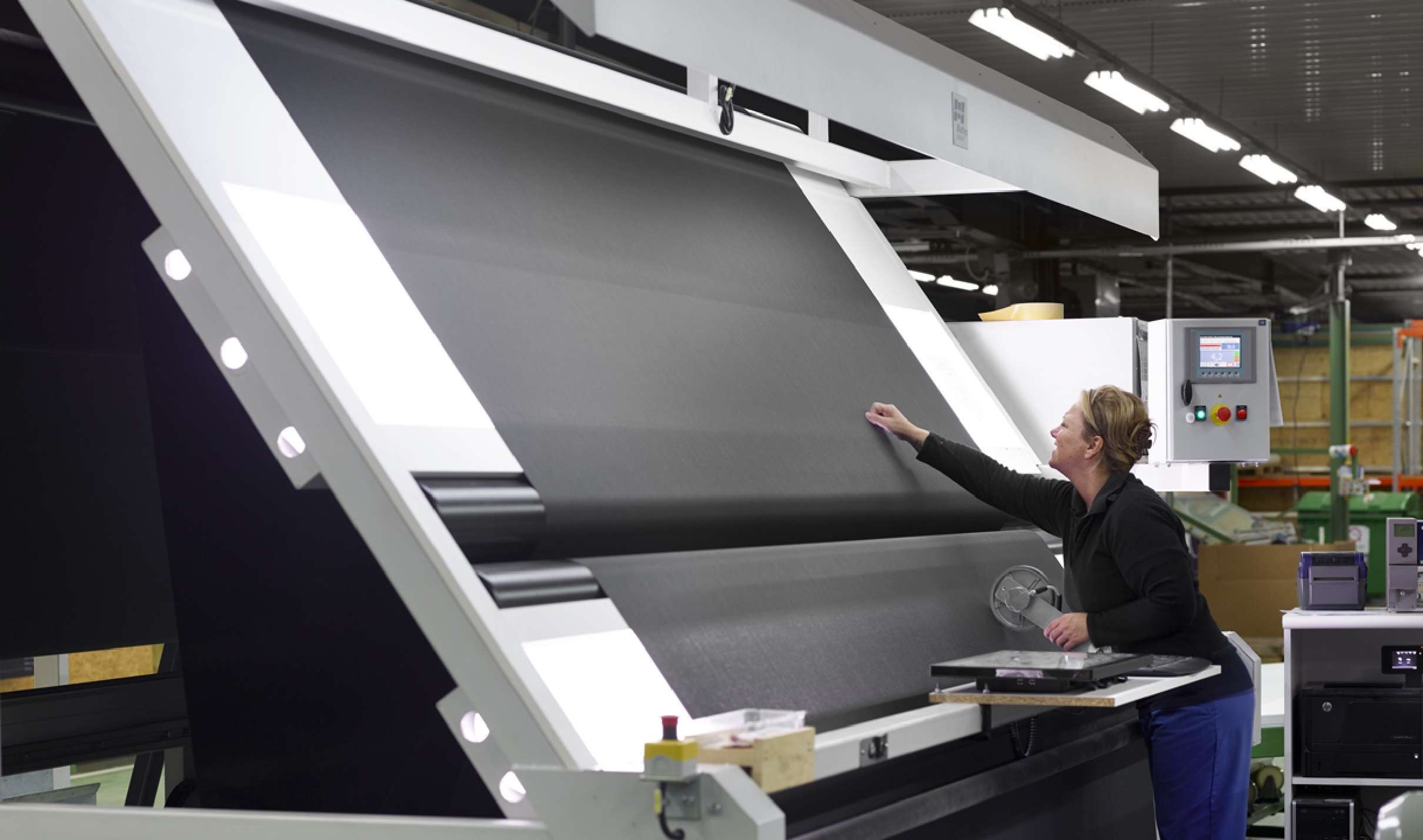

Helioscreen, part of Dutch multinational Hunter Douglas, has built a global reputation as a manufacturer of fiberglass sun protection fabrics. The company focuses mainly on tailormade screen fabrics and fabric by the roll. Its products are shipped worldwide or used for the in-house production of solar screens.

In 2018, Helioscreen decided to take the next step in creating a digital factory, by implementing a manufacturing execution system (MES) built with open source components. Smart manufacturing software allows them to combine data capture, connectivity, remote control and analytics, aiming to improve their overall equipment effectiveness with Factry OEE.

Helioscreen’s main challenges were to enhance productivity, streamline manufacturing operations, improve delivery reliability and eliminate paperwork. Therefore, they wanted to monitor and control the production process through a single platform for operations management, that has been integrated with other systems.

A clear sign of the factory’s improved efficiency is the fact that the planning parameters we used before no longer match reality.

Stefaan Claeys

Operations Manager at Helioscreen fabrics

Before, they lacked an integrated bird’s-eye view of the factory’s overall production process. This made it impossible for Helioscreen to manage with sufficient flexibility, buffer and make last-minute changes to production orders, which would result in a larger stock.

Another issue Helioscreen was dealing with was communication from the planning department towards the factory floor and vice versa. Previously, planners used both the enterprise resource planning (ERP) software and paper notes to instruct operators, often leading to errors, delays and downtime.

Thanks to Factry solutions, those days are gone.

Currently, at Helioscreen, a Historian database running in the background collects data from production equipment. Factry’s MES interfaces the Historian data back and forth to the ERP to keep production planning up-to-date, while the data is also being displayed on tablets on the factory floor, close to the machines.

Once connected to the machine hardware, Factry Historian delivered instant value by immediately starting to capture data, even months before the MES was added to it. This also makes the MES system more modular and scalable, without having to develop a separate machine interface in the MES.

Apart from tablets displaying the machine data, operators now see all current production orders lined up on large communication screens spread throughout the factory, including all tasks needed to avoid unplanned downtime. They get all the information they need right when they need it, in an easily accessible, user-friendly way.

Operators are not robots. Factry MES gives them the right information at the right time through user-friendly communication screens.

Stefaan Claeys

Operations Manager at Helioscreen fabrics

The MES software predicts when changeovers are needed, e.g. to replace colours or a docking station. Since operators now know exactly what is coming up next, operators can align their actions and reduce planned downtime by no less than 65%. Even tiny micro-stops are registered for further analysis.

When order planning is adjusted last-minute, people on the floor are immediately notified. Adjusting an order used to take 30 minutes, whereas now, it is completed in 2 minutes. This allows the factory’s staff to make last-minute changes to any production order, without experiencing additional stress on the factory floor.

Through open and web-based technology, Factry MES gives remote access to the production data to an unlimited number of employees. Planning department employees can work from home, using the same screens, displaying real time information on planning, orders and efficiency.

“A clear sign of the factory’s improved efficiency is the fact that the planning parameters we used before no longer match reality. We can also predict when specific standstills will happen and align our actions accordingly. Whereas a machine used to be at a standstill for half an hour, it is now down for just ten minutes.”

“Operators are not robots. Factry MES gives them the right information at the right time through user-friendly communication screens. It provides them with clear expectations and added freedom to organise their work. This also means that the people on-site can be deployed more efficiently.”

“Overall, the implementation and collaboration process went smoothly. The biggest challenge? Developing the communication screens for the operators on the factory floor. This aspect needed some adaptations and extra coding along the way, but Factry was very open to it. They are very flexible.”

“The remote working feature of our MES platform has proven to be a great asset during the Covid-19 pandemic. During lockdown, we experienced zero impact on the production process, while fully respecting social distancing. Without Factry MES, our returns would have surely been lower.”

“There is always a lot of goodwill, effort and drive. The people at Factry genuinely believe in the strategy they have designed and go the extra mile to make things happen. And since Factry builds its software solutions with open source technology, there is no vendor lock-in. You are not stuck with a traditional big player on the market.”

The remote working feature of our MES platform has proven to be a great asset during the Covid-19 pandemic.

Stefaan Claeys

Operations Manager at Helioscreen fabrics

Predictive analysis

Factry MES drastically reduces unplanned downtime through predictive analysis. By knowing what is coming, people can now plan their actions better with more freedom, while even small patterns are noticed straight away.

Fluent integration

In order to communicate fluently with both new and older machinery, additional coding was required. Smooth interaction with any on-site hardware is guaranteed, through implementing low-level protocols in Factry Historian.

Bird’s-eye view insights

Bird’s-eye view screens across the production site display the entire working organisation: how things are proceeding on the floor, what tasks are new, which standstills need to be handled. This information is displayed on a team level.

Easy-to-use interface

Machine data is displayed on a tablet and an easy-to-use interface, mounted onto the hardware. However, the software is not restricted to a single device. You simply need an internet browser to get the system up and running.

Fast user adoption

The first rule for user screen adaptation is making sure it definitely works before you introduce it. As many people were involved in the design process and the user screens were thoroughly tested, user adaptation went quickly.

Factry is a Belgian software company, which was founded in 2016. Being a start-up does not mean we are new kids on the block. Our team has over 20 years of experience in the global manufacturing and processing industry.

Our core mission is to introduce data-driven operational improvement and better insights to our clients, by offering them a scalable platform to easily collect, store and visualise sensor data from any type of industrial equipment.

We are not an automation company that develops software and drivers on the side. We are IT experts who are very knowledgeable about all aspects of automation. We look at things from an IT perspective, aiming to open doors to new and innovative solutions.

We are different. We are Factry.